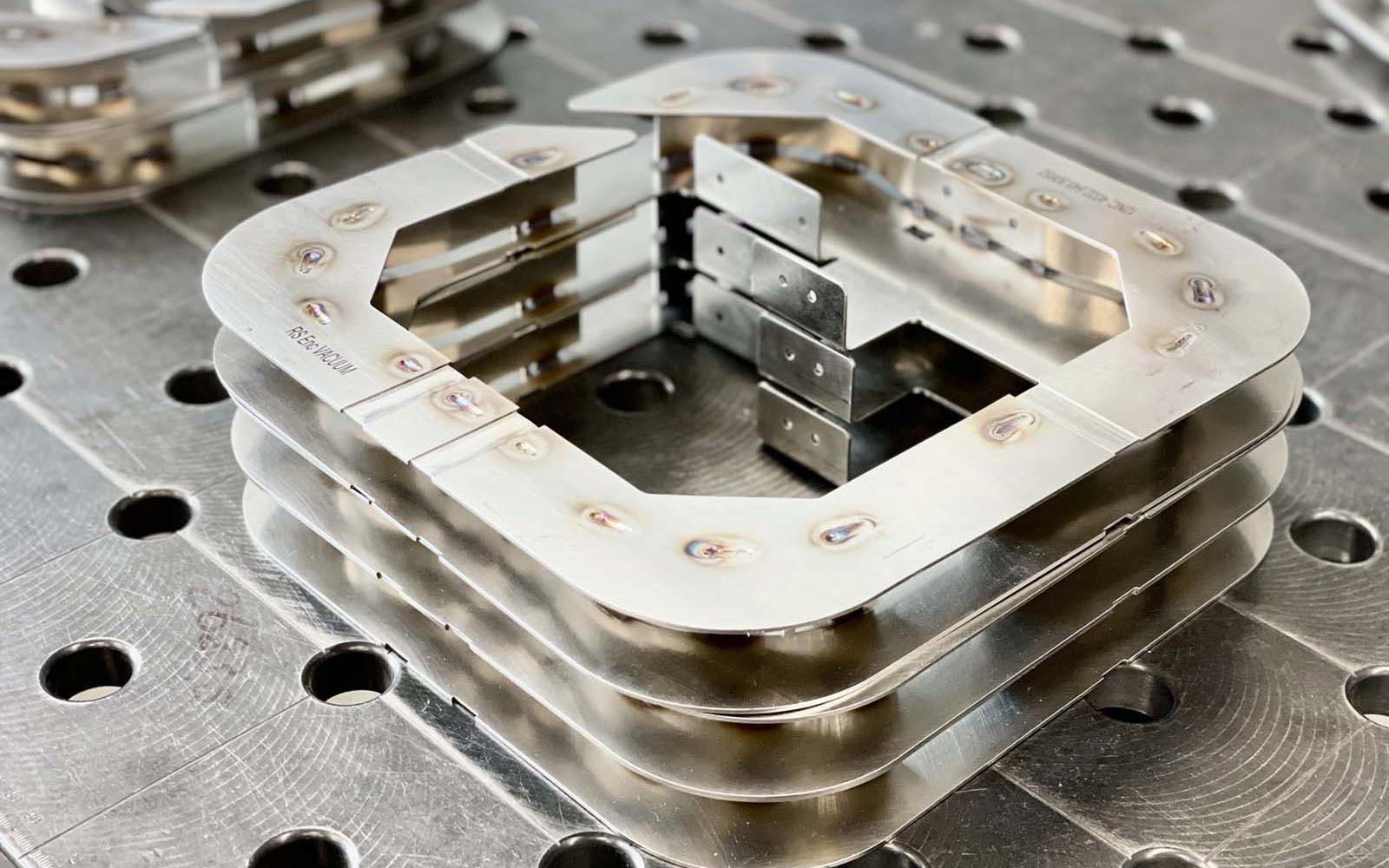

Your partner for complex welding assemblies in the food industry

Are you an OEM looking for a reliable partner for complex weld assemblies in the food industry? Or are you a food producer seeking weld connections that meet the highest hygiene standards?

Complex weld assemblies are advanced weld connections used when standard welding methods do not meet the requirements. These processes require specialized knowledge and skills, including advanced welding techniques, to comply with the strict hygiene and safety standards of the food industry.

At RVS Non Ferro, we specialize in delivering high-quality complex weld assemblies for the food industry. Our weld connections are strong, durable, hygienic, and meet high-quality standards.