Complete assembly for high-quality machines

At RVS Non Ferro, assembly is about fully assembling machines, both mechanically and electrically. To ensure a smooth and flawless process, we work with precision and efficiency. Our approach is based on the right sourcing channels, a solid strategy, and well-thought-out management, resulting in high-quality end products that meet all expectations.

We handle the complete mechanical and electrical assembly of your machines. Our experienced technicians work to the highest quality standards, ensuring that every part fits and functions perfectly. This includes:

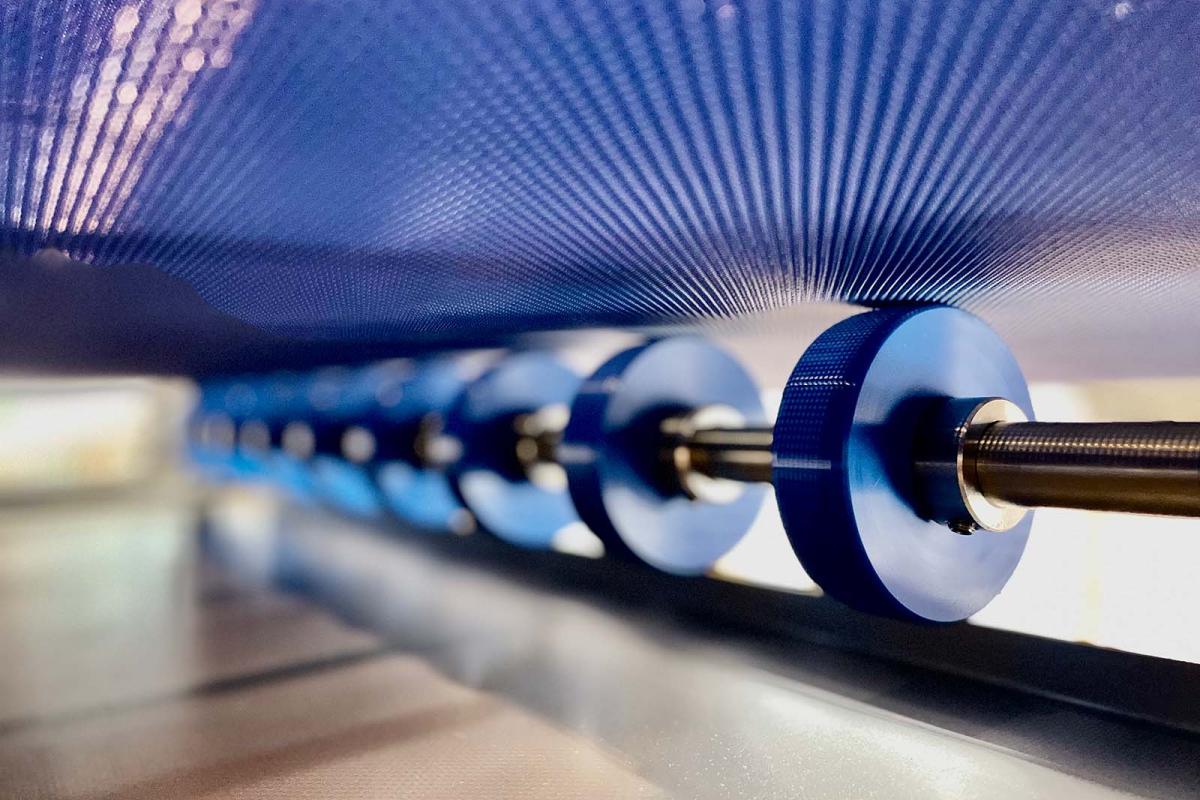

Mechanical assembly: Assembling moving parts, frames, enclosures, and other mechanical components.

Electrical assembly: Installing electrical systems, wiring, control panels, and electronic components.

With our expertise in both mechanical and electrical assembly, we ensure seamless integration between all parts.